why use brinell hardness test|brinell hardness test errors : solutions The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to . Resultado da Watch the Most Relevant Cavalgando Gostoso Porn GIFs right here for free on Pornhub.com. Sexy and hardcore lesbians, cartoon and funny porno .

{plog:ftitle_list}

Watch Gotham — Season 5, Episode 1 with a subscription on Max, or buy it on Vudu, Amazon Prime Video, Apple TV. Jim Gordon and Bruce Wayne face the chaos Gotham .

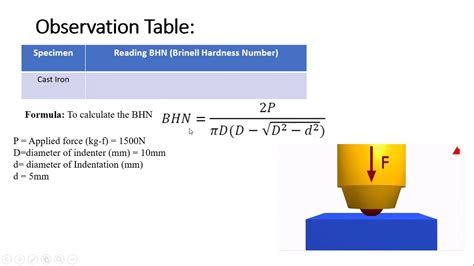

how to calculate brinell hardness

The Brinell Hardness Test method is the most commonly used hardness measurement technique in the industry. In the Brinell Hardness Testing, the hardness of a metal is determined by .

2. Brinell Hardness Test. The Brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the material. The diameter of the indentation is .

The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to .Proposed by Swedish engineer Johan August Brinell in 1900, it was the first widely used and standardised hardness test in engineering and metallurgy. The large size of indentation and possible damage to test-piece limits its usefulness. However, it also had the useful feature that the hardness value divided by two gave the approximate UTS in ksi for steels. This feature contributed to its early adoption over competing hardness tests.

The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested .Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading . Currently, it is most commonly used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested using another test method, e.g., castings and forgings using very high-test loads. In summary, the Brinell Hardness Test’s ability to provide representative hardness values over larger areas, coupled with its ease of use, makes it a valuable choice for certain metallurgical applications. By .

brinell hardness testing machine diagram

The Brinell method can be used for testing non-homogeneous materials (e.g. castings), because the large ball comes into contact with many crystals (different metallographic .Why do Brinell and Vickers Hardness Test Results Show Similarities? For Brinell and Vickers hardness test, the similarities in results often come from the use of an optical instrument to measure the indentation made on the material surface. They both require an optical instrument to measure the indentation to ascertain the hardness values of .In the Brinell hardness test method, only one type of indenters is used while in Rockwell hardness we use two types of indenters for the procedure of the test. In the Brinell test, the intender is a calcareous ball or hard metal. In the Rockwell hardness test, intenders are a small steel ball (or soft objects) and a diamond cone for hard .

The Brinell hardness test records the diameter and depth of the indentation caused by a ball-shaped indenter, with the indenter pressed into a material's surface. This is the guide on how to read and represent brinell hardness values. . Why Use the Brinell Hardness Value?Brinell Hardness Tester holds significant importance in today's industrial landscape, where understanding material properties is crucial for ensuring product quality, reliability, and performance. This test reveals vital information about their hardness, toughness, and suitability for specific applications by subjecting materials to controlled indentation.Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter .

Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load).

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and .The Brinell hardness meter uses an impulse force of 9.807N to 29420N depending on the test material and the diameter of the impeller ball. The load is usually applied for 10 to 15 seconds in the case of testing steel or steel materials, and for other softer materials the load must be applied at least 30 seconds.Brinell Hardness Test. Brinell hardness test is one of the indentation hardness tests developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 .

Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. Capabilities. Processes. Heat Treating. Annealing; . hardness values derived from the test provide a more representative average hardness of the part. More information about Brinell testing can be found in ASTM .An alternative method is the Brinell hardness test, which uses a hardened steel (or tungsten carbide) ball indenter with a diameter D of, usually, 10 mm.This is applied under a load P of 500–3000 kg applied for 10–30 s.The diameter of the circular indentation d is measured in millimetres. The hardness number, (HB) is calculated using the following equation:

The Brinell hardness test is used for hardness testing larger samples in materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression, using a tungsten carbide ball. The size of the indent is read optically.The Brinell hardness test, which is relatively slower than other methods, can be used for microhardness and microhardness testing. This method can be used to test materials that have coarse or inhomogeneous surfaces that other methods cannot be used. Brinell hardness test uses a steel or tungsten indenter of a specified size and a specified .

Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and aluminium alloys, while the 3000 N load is often used for testing harder materials such as steels and cast irons.However, the general rule is that the combination of test load and ball diameter .

brinell hardness testing charts

Brinell Hardness Test. The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test uses a desktop machine to apply a specified load to a hardened sphere of a specified diameter. The Brinell hardness number, or simply .The Brinell hardness test is preferred where you cannot use other methods to inspect rough materials. This is the main reason why this method has evolved over time. The need for accuracy, precision, reliability, and ease of use when carrying out the Brinell hardness test contribute to its popularity as a measurement tool.As per the name, the Brinell hardness test is used to determine the hardness of the given material and this hardness test is in use for many years. As per its definition, a small metal ball acts as the indenter and a force is applied on the . 1.5 At the time the Brinell hardness test was developed, the force levels were specified in units of kilograms-force (kgf). Although this standard specifies the unit of force in the International System of Units (SI) as the Newton (N), because of the historical precedent and continued common usage of kgf units, force values in kgf units are provided for information .

The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the impression is measured with a microscope with a superimposed scale. The Brinell hardness number is computed from the equation: There are a variety of test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell).The Brinell Hardness Test is most typically used for testing materials that have an extremely coarse structure or when the surface is too rough for testing using another test method, such as castings and forgings.. Image Credit: Tinius Olsen. Brinell testing generally applies a very high test load (3000 kgf) with a 10 mm diameter indenter so that the indentation averages out the .2. Brinell Hardness Test. The Brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the material. The diameter of the indentation is measured to calculate the Brinell hardness number (HB). This method is ideal for testing softer or larger materials like cast iron and steel.The difference between Vickers method and the Brinell method is that the Vickers use pyramid-shaped indenter, whereas the Brinell method uses a spherical indenter. Brinell test methods are defined in the following standards-ASTM E10; ISO 6506; JIS Z 2243 ; Equipment Required. Brinell hardness tester RAB-250; Brinell microscope; Indentors (2.5mm .

The Brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by applying a known load to the surface of the tested material through a hardened steel ball of known diameter. The diameter of the resulting permanent impression in the tested metal is measured and the Brinell Hardness .

The typical brinell hardness test uses a 10 millimeters (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29 kN; 6,600 lbf) force. For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation is measured and hardness calculated as:What is a Brinell Hardness Test? The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to 3000Kgf, for a specified time period, usually between 10 and 30 seconds. Depending on the specific application, the load is .In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves a pyramid-shaped indenter being pressed into a specimen, the Brinell method uses a spherical indenter.Units of hardness. There are a variety of hardness test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). There are tables that are available correlating the hardness numbers from the different test methods where correlation is applicable.

brinell hardness tester diagram

polarimeter principle and working

Por Redação em Imagens da Semana em 03 de setembro d.

why use brinell hardness test|brinell hardness test errors